Powders play a vital role in many industries, from food products like cocoa powder to minerals and the lifesaving medications pharmaceutical manufacturers create. Their colors must be consistent and meet customer expectations to support quality initiatives, conformance with industry standards, satisfaction, and, ultimately, profitability. Spectrophotometers provide the easiest, fastest, and most objective way to quantify color to help you reach these goals.

Key Features to Evaluate

Learning what key features to evaluate as you explore the spectrophotometric solutions available can help you make a more sound investment.

Minimum Sample Sizes

Some ingredients, like certain high-value spices and active pharmaceutical components, are incredibly expensive. Reducing the size of the sample needed for accurate measurements is key to controlling waste and limiting sampling costs. A spectrophotometer that offers the smallest sample size possible will deliver the most value for many applications and significantly lessen the expenses involved with high-value powder production.

Sample Compatibility

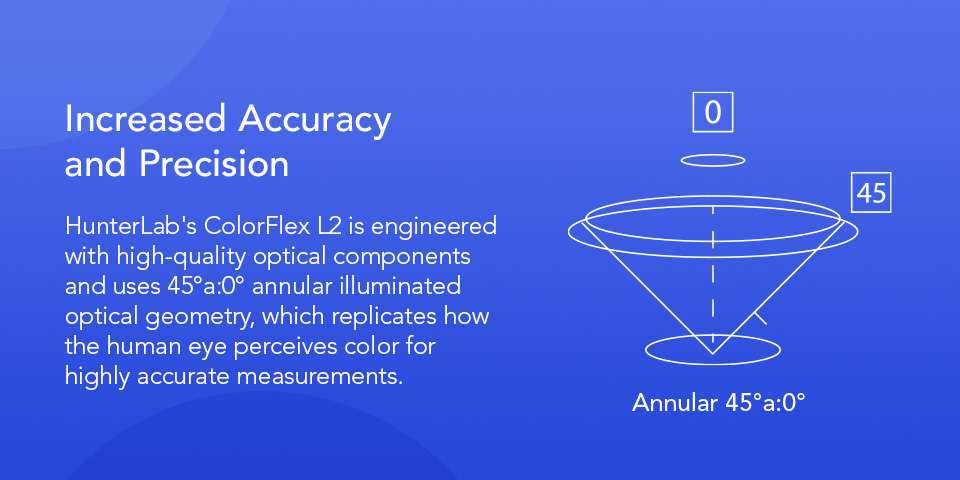

Powders present unique challenges in color measurement. Many have nonuniform textures and varying particulate sizes requiring careful sample preparation to promote accurate outcomes. Their opacity demands specialized optical geometry that captures data through reflectance. A thorough, careful analysis of your powder's physical properties will help ensure the spectrophotometer's capabilities align with your needs.

Index and Scale Library

Many industries have specific industry scales or indices they use to ensure their products conform to standards. Samples may rely on different color spaces, such as the CIELAB scale often used to measure barium sulfate. Evaluate the spectrophotometers you're considering to ensure they're capable of providing data within the scales that apply to your industry.

Effective Bandwidth

Regardless of which wavelength you measure in the visible spectrum, you need to ensure the device you select has suitable effective bandwidth for accuracy. This term refers to the range of wavelengths interacting with a sample at a given moment. A narrow effective bandwidth coupled with high radiation throughput helps ensure strong signals and background noise reduction. This configuration allows for more precise readouts since the spectrophotometer can isolate smaller wavelength ranges.

Integration Capabilities

Ideally, the spectrophotometric solution you choose should fit effortlessly into existing workflows instead of forcing you to adapt proven processes. Features like universal compatibility simplify integration. This trait allows the spectrophotometer to connect to and communicate seamlessly with other devices. In addition, selecting a model with many connectivity options makes data export and transfer to your quality management systems fast and easy.

Viewing Area

While finer powders may lend themselves to a smooth, even sample surface, sample averaging is critical for measuring color in powders with larger particles and nonuniform characteristics. These traits can lead to shadowing that can create measurement discrepancies when only capturing data in one reading. Taking multiple measurements across larger viewing areas and averaging them helps resolve those challenges, so it's essential to consider viewing area size as you narrow down the options.